TURN-KEY AdBlue®

PRODUCTION PLANT

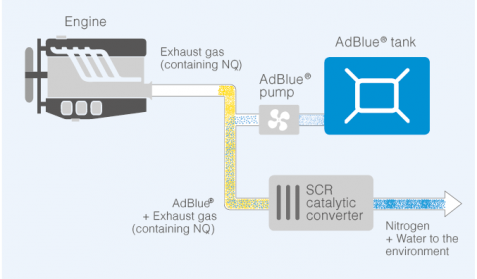

Euro 5 and 6 emissions standards

Euro 5 and 6 emissions standards

AdBlue® PRODUCTION SIDE

PROFITABLE - FAST - SMART

WHAT MAKES THIS PLANT THE BEST CHOICE

The name of our system is COLD PRODUCTION PROCESS has a lot of advantages

Profitable Production

As you know, the Urea's reaction in the water is endothermic. so, when put urea, Delta T will be almost 15 Degrees of Celsius dropped down. Traditional systems need 75 kW of heating energy for dissolving Urea, While our system just uses 15 Kw. It means low unit cost and more profit.

Fast Production

For each batch production time is almost 20 minutes. means that very low energy for fast production While conventional systems require at least 2 hours for heating and mixing.

Smart Production

Our system is controlling and mixes automatically without touch. Taking Urea, taking water amount mixing checking percentage online. if see any low or high percentage, adding-adjusting water or urea accordingly. so, no wasted batch, saving time, saving energy.

Minimum Manpower

Just 1 staff is enough for the production. That staff will load big bag of Urea to the Urea hopper and he/she will have 3 free hours to check the system by the monitor. and he/she will check quality control after 3 hours, that is all.

Certificates & Standards

VDA Certificate

ISO 9001

ISO 13485

ISO 14001

Duty Free

We supply the A.TR file. It means that you will not pay Tax on your border.

OTHER STRENGTS

We provide a variety of high-tech solutions with our diverse product portfolio.

FULL AUTOMATED AdBlue® Production

- Transfers urea from the hopper

- Calculates the water amount is needed

- Transfers water from UPW System

- Analyzes the mixture continues mixing

- Transfers AdBlue to the stock tanks

- No wastage/loss in production batches

- Saves time, energy, and urea loss

Equipped with accurate sensors

- Counting or weighing the Urea sacks in our Production Systems is unnecessary.

- The sensors automatically transfer Urea to the Mixer as needed.

VDA Certificate Cosultancy

- After starting production, full consultancy for getting VDA certificate in one of our service

User Friendly UX/UI Design

Online Access and Intervention

MODELS

ADB 1800

CAPACITY: 2 m3/h

ELECTRIC: 380 V - 10 kW

NEEDED AREA: 300 m3

ADB 4800

CAPACITY: 6 m3/h

ELECTRIC: 380 V - 12 kW

NEEDED AREA: 350 m3

ADB 7200

CAPACITY: 9 m3/h

ELECTRIC: 380 V - 15 kW

NEEDED AREA: 400 m3

ADB 9600

CAPACITY: 12 m3/h

ELECTRIC: 380 V - 15 kW

NEEDED AREA: 450 m3

ULTRA WATER PURIFICATION

BASED ON ISO 22241

TRIPLE PASS RO SIDE

ssss

WATER SPECIFICATION

| Characteristics | Unit | Drinking Water (ISO: 10500) | Deionized Water (ISO 22241) |

|---|---|---|---|

| Aluminum | mg/l Max | 0.03 | 0.5 |

| Calcium | mg/l Max | 75 | 0.5 |

| Iron | mg/l Max | 0.3 | 0.5 |

| Magnesium | mg/l Max | 30 | 0.5 |

| Conductivity | μS/m | 5,000-50,000 | 5.5 |

THE EFFECTS OF WATER AND UREA QUALITY ON THE SCR SYSTEM

AdBlue® by Our System

-

Reduces maintenance costs

- Extends SCR system lifespan

- Ensures SCR system efficiency

- Improves fuel economy

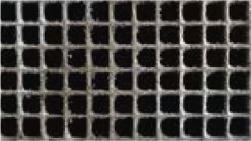

SCR system after 40,000 km

using AdBlue® by Our Urea

- Reduced SCR system lifespan

- Increased emission of pollutants

- Clogged catalytic converter

- Clogged exhaust and injector

SCR system after 40,000 km

using low-quality urea solution

AdBlue® Specifications During VDA Standards

| APPEARANCE | CLEAR LIQUID | DN 8-53 |

| UREA CONTENT | 32.5 ± 0.7 | ISO 22241-2 |

| ALKALINITY AS NH3 | 0.2 % MAX | ISO 22241-2 |

| REFRACTIVE INDEX AT 20°C | 1.3814 – 1.3843 | ISO 22241-2 |

| BIURET | 0.3 WT% MAX | ISO 22241-2 |

| ALDEHYDES | 5.0 MG/KG MAX | ISO 22241-2 |

| INSOLUBLE MATTER | 20 MG/KG MAX | ISO 22241-2 |

| PHOSPHATE (PO4) | 0.5 MG/KG MAX | ISO 22241-2 |

| CALCIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| IRON | 0.5 MG/KG MAX | ISO 22241-2 |

| COPPER | 0.2 MG/KG MAX | ISO 22241-2 |

| ZINC | 0.2 MG/KG MAX | ISO 22241-2 |

| CHROMIUM | 0.2 MG/KG MAX | ISO 22241-2 |

| NICKEL | 0.2 MG/KG MAX | ISO 22241-2 |

| SODIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| ALUMINIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| MAGNESIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| POTASSIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| IR | YES | IDENTICAL TO REFERENCES |